Locker Material Compared: Particle Board VS Medium Density Fiber Board

Particle board and medium density fiber board are common materials used in commercial lockers. Both particleboard and MDF or medium density fiberboard are pressed wood products that are formed by using a hot press machine that literally squeezes the component materials into flat boards of varying thickness. Particleboard and MDF share advantages over solid wood and plywood in terms of density, uniformity, and price. Comparing the price, density, strength, and durability of particleboard and MDF, you will find that they are quite similar. However, they are different in some ways.

What is particle board?

Particle Boards are a relatively new type of engineered wood product that are made from glueing together small chips and saw-dust and firmly pressing them together to make boards or sheets. With particle board furniture becoming more commonly available in the market it is useful to know how it compares with other types of engineered woods such as plywood and with solid wood. Made from a hot pressed composite of wood-based waste materials bound together with formaldehyde resin, particleboard is a dense building material used commonly since the 1960s. Good for numerous applications including countertops, cabinetry, doors, floors, wall paneling, and furniture, particleboard is denser than wood and therefore stronger. When coated with veneer or painted, its outward appearance improves. Compared to other fiberboards or composite, wood-based building materials, it is weaker.

Particle Boards are a relatively new type of engineered wood product that are made from glueing together small chips and saw-dust and firmly pressing them together to make boards or sheets. With particle board furniture becoming more commonly available in the market it is useful to know how it compares with other types of engineered woods such as plywood and with solid wood. Made from a hot pressed composite of wood-based waste materials bound together with formaldehyde resin, particleboard is a dense building material used commonly since the 1960s. Good for numerous applications including countertops, cabinetry, doors, floors, wall paneling, and furniture, particleboard is denser than wood and therefore stronger. When coated with veneer or painted, its outward appearance improves. Compared to other fiberboards or composite, wood-based building materials, it is weaker.

Advantage of particle board

Particleboard is environmentally friendly. This is one often-overlooked advantage to using particleboard whenever possible. Particleboard is made from the scraps of other lumber products. This means that there is no waste when particleboard is manufactured, and no extra logging need be done to produce particleboard. Some particleboard is also manufactured without the use of formaldehyde, a chemical that can cause medical problems. Check with the manufacturer or even the lumberyard or store where you purchase the particleboard to find out which varieties are formaldehyde free; it may also be plainly marked on the particleboard itself.

Disadvantage of particle board

Particleboard is at a disadvantage in that it can expand when exposed to moisture. Outdoor use is almost never a good idea, even when it is covered with a sealing agent. In bathrooms and kitchens, it may be used as the foundational material so long as it is covered with moisture-proof vinyl. Particle board furniture is quite weak compared to other kinds of engineered woods such as plywood. It is less dense and can easily get damaged while handling. So for those who need to shift from one house to another quite frequently, its important to note that their particle board furniture may not survive the ordeal. Apart from being low on strength, particle boards are also prone to getting damaged because of moisture and humidity. This means that furniture made from these boards will not last very long. This is without doubt the major drawback of particle board furniture.

What is medium density fiber board?

MDF is an engineered wood composite that is similar to particle board, but is much denser and stronger than particle board. Imagine if all of the sawdust was swept up from other wood product manufacturing processes, and then that sawdust was mixed with binders and pressed into large sheets the size of plywood. Okay, that’s way oversimplified, and it’s not exactly the process they use to make MDF, but that gives you an idea of the makeup of the product.

MDF is an engineered wood composite that is similar to particle board, but is much denser and stronger than particle board. Imagine if all of the sawdust was swept up from other wood product manufacturing processes, and then that sawdust was mixed with binders and pressed into large sheets the size of plywood. Okay, that’s way oversimplified, and it’s not exactly the process they use to make MDF, but that gives you an idea of the makeup of the product.

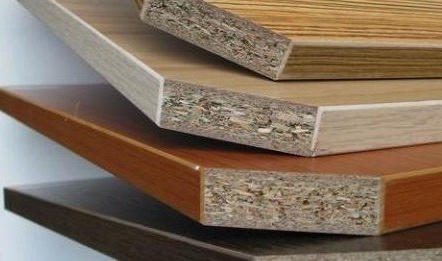

Because it’s composed of such small wood fibers, there’s no wood grain in MDF. And because it’s pressed so hard at such high temperatures, there are no voids in MDF like you find in particle board. Here you can see the visible difference between particle board and MDF, with MDF on the top and particle board on the bottom. Just like plywood, you can purchase MDF in different thicknesses depending on what you need for your project.

Advantages of MDF

MDF is generally cheaper than plywood. The surface of MDF is very smooth, and you don’t have to worry about knots on the surface. Because it’s so smooth, it’s a great surface for painting. I recommend first priming with a quality oil-based primer. (Don’t use aerosol spray primers on MDF!! It just soaks right in, and is a huge waste of time and money. It will also cause the surface to become rough). Also because of its smoothness, MDF is a great substrate for veneer. MDF is very consistent throughout, so cut edges appear smooth and won’t have voids or splinters. Because of the smooth edges, you can use a router to create decorative edges. The consistency and smoothness of MDF allows for easy cutting of detailed designs (such as scrolled or scalloped designs) using a scroll saw, band saw, or jigsaw.

Disadvantages of MDF

MDF is basically glorified particle board. Just like particle board, MDF will soak up water and other liquids like a sponge and swell unless it’s very well sealed on all sides and edges with primer, paint, or another sealing product. Again, I recommend a quality oil-based primer. No aerosol spray primers!!Because it consists of such fine particles, MDF doesn’t hold screws very well, and it’s very easy to strip the screw holes.

Because it’s so dense, MDF is very heavy. This can make it more difficult to work with, especially if you don’t have a helper who can help you lift and cut the large sheets. MDF can’t be stained. Not only does it soak up stain like a sponge, but also because there’s no wood grain on MDF, it looks awful when it’s stained. (Kind of like staining particle board. Why would you bother?) MDF contains VOCs (urea-formaldehyde). Off gassing can be greatly minimized (but probably not eliminated) if the MDF is encapsulated with primer, paint, etc., but care needs to be taken while cutting and sanding to avoid inhalation of the particles. I recommend cutting and sanding outside while wearing a particle mask.